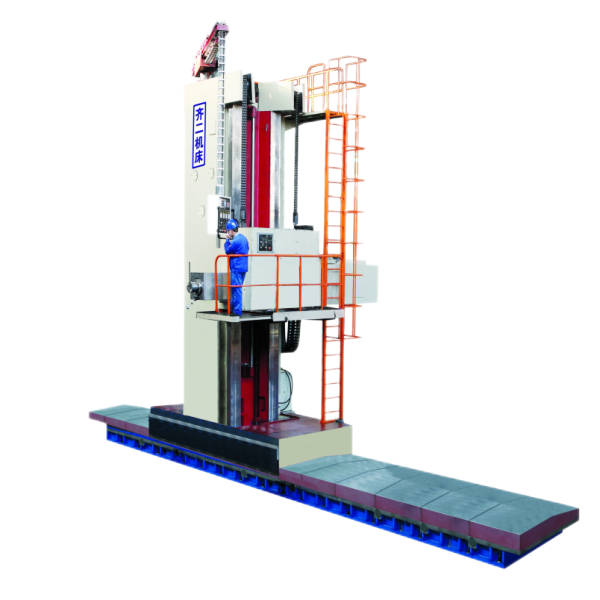

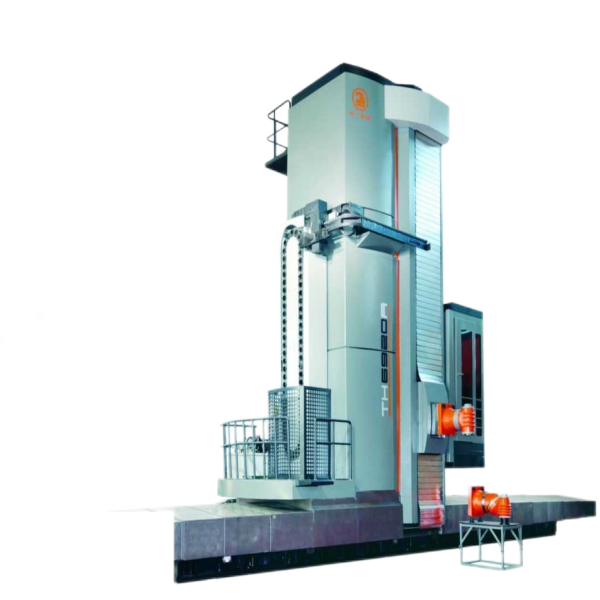

TH69 Series CNC Floor Type Milling And Boring Machining Center

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. New floor type 5 axis milling machine has good wear resistance and shock absorption.

2. New floor type 5 axis milling machine has large low frequency torque and stable output.

3. New floor type 5 axis milling machine has fast torque dynamic response and high speed stabilization accuracy.

Through a breakthrough technical architecture, our new floor type 5 axis milling machine redefines the boundaries of efficiency and accuracy for heavy-duty machining. Without frequent clamping and debugging, the integrated molding of complex workpieces can be achieved, helping your production line break through production capacity bottlenecks and deliver high-quality products in a shorter period of time. Whether it is a single-piece customization or mass production, it can meet the needs of high-intensity processing with excellent stability.

Customized services of products:

For the processing challenges of different industries, our new floor type 5 axis milling machine supports modular configuration and functional expansion. Whether it is the processing of precision parts or the manufacturing of heavy-duty components, it can meet your special process needs through customized solutions. Our professional team will work closely with you to tailor an efficient processing plan that meets your production goals.

Design of products:

We deeply integrate ergonomics and intelligent interaction to create an intuitive and convenient operation interface and a comfortable and safe operating environment for the new floor type 5 axis milling machine. Whether it is touch-screen control or optimized equipment layout, it is to reduce the burden on the operator and improve the comfort and accuracy of long-term operation.

Flexible production solutions of products:

Facing the rapid changes in market demand, the limitations of traditional equipment have become production bottlenecks. Our new floor type 5 axis milling machine breaks boundaries with a modular design, supporting fast process switching and flexible function expansion. Whether it is small-batch customization or multi-variety mixed-line production, it can be easily handled, allowing your production line to freely adapt to different tasks and maintain the agility of market response.

Compliance of products:

New floor type 5 axis milling machine strictly follows the top international safety and quality certification system, and can operate in compliance in any production environment around the world. We have always provided technical response and original factory-level after-sales support, and escorted the whole process from pre-sales to after-sales, allowing you to focus on your core business without worries.

Specifications of machining center:

Specification/Model | Unit | K6913B/TH6913B | TK6916B/TH6916B | TK6916/TH6916 | TK6920/TH6920 | TK6920A/TH6920A | TK6926B/TH6926B | TK6932/TH6932 |

Boring Spindle Diameter | mm | Φ130 | Φ160 | Φ160 | Φ200 | Φ200 | Φ260 | Φ320 |

Boring Spindle Taper (7:24) | ISO50 | ISO50 | ISO50 | ISO60 | ISO50 | ISO60 | ISO60 | |

Milling Spindle End Diameter | mm | Φ254 | Φ280 | Φ320 | Φ320 | Φ320 | Φ400 | Φ450 |

Ram Section | mm | 380×400 | 440×480 | 480×520 | 480×520 | 480×520 | 600×650 | 680×780 |

Column Travel ( can be extended) Axis X | mm | 4000 | 6000 | 6000 | 8000 | 8000 | 10000 | 18000 |

Headstock Travel (can be extended) Axis Y | mm | 2000 | 3000 | 3000 | 4000 | 4000 | 5000 | 8000 |

Boring Spindle Travel (Axis Z) | mm | 700 | 1000 | 1200 | 1200 | 1200 | 1700 | 1800 |

Ram Travel (Axis W) | mm | 900 | 1000 | 1200 | 1200 | 1200 | 1700 | 2000 |

Headstock Speed Range, III Shifts | rpm | 2-1500/3.2-2500 | 2-1500 | 2-1000 | 2-1000 | 2-2500 | 2-800 (1000) | 2-600 |

Feed Rate of Boring Spindle and Ram, Infinitely Variable | mm/min | 0.6-8000 | 0.6-4000 | 1-3000 | 1-3000 | 1-10000 | 1-3000 | 1-3000 |

Feed Rate of Column and Headstock, Infinitely Variable | mm/min | 1-8000 | 1-6000 | 1-6000 | 1-6000 | 1-15000 | 1-6000 | 1-6000 |

Main Motor Power | kw | 37 | 60 | 55 | 71 | 60 | 100 | 129 |

Tool Magazine Capacity | Pc. | 40 (Machining center) | 60 (Machining Center) | 60 (Machining Center) | 60 (Machining Center) | 60-100 | 60 (Machining Center) | 80 (Machining Center) |

Introduction of the application and characteristics of new floor type 5 axis milling machine:

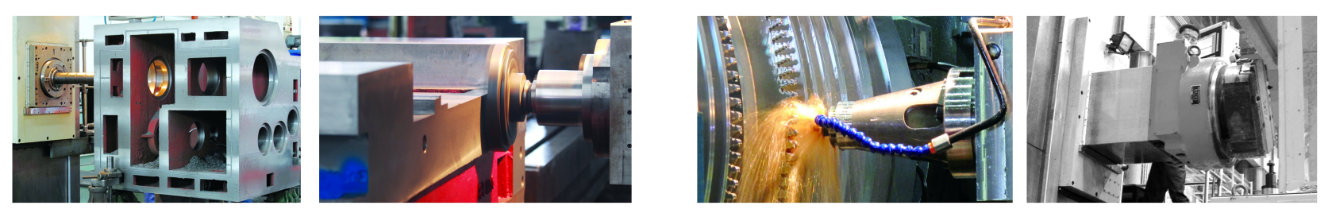

It adopts headstock structure with moving ram for both CNC floor type milling and boring machines, series TK69 and CNC floor type milling and boring machining center, series TH69. Our company independently developed new floor type 5 axis milling machine with independent intellectual property. New floor type 5 axis milling machine have reliable performance with the application of multiple advanced technologies, such as the double pinion and rack backlash free structure or dual motor with double pinion and rack transmission provided for Axis X. There are preloaded backlash-free high precision ball-screw trans mission structure provided for Axes Y, Z and W. The multi-pocket closed hydrostatic guideways structure is applied on the guideways of the Axes Y, Z and W, which has low difference between dynamic and static friction coefficients and no stick and slip at low speed. The pressure in each hydrostatic oil pocket is controlled by the damper with capillary spiral tubes, which have features of simple structure, small occupying space, and convenient adjustment. The CNC systems on new floor type 5 axis milling machine is capable of simultaneous motion control on any four axes and simultaneous five axes motion control, if the high precision two-axes swivel milling head is mounted. New floor type 5 axis milling machine are equipped with vertical milling head, universal milling head, extended milling head and CNC rotary table, and they are especially appli cable for machining super heavy-duty workpieces with complex contour shapes. New floor type 5 axis milling machine can accomplish milling, boring, taping, and machining of contour surfaces and lines in 5-D coordinate system (eg. propeller blades, etc.) with high precision and rigidity, and they are the hydro- mechatronic products integrated with high automation and technologies.

New floor type 5 axis milling machine of series TK69 and TH 69 are the key equipments urgently required in domestic heavy-equipment and important industries. This series of new floor type 5 axis milling machine are first developed and produced in the domestic market of China and they can replace the new floor type 5 axis milling machine imported from overseas suppliers. They have reached the advanced level of similar products contemporarily around the world, with much lower market prices. Our company provide after sales services and spare parts in time after the request received and we deliver the services and parts much faster than the foreign suppliers do. Thus, this series of new floor type 5 axis milling machine have strong competitiveness in the international market. New floor type 5 axis milling machine can be widely applied in military industry, energy industry, wind power industry, nuclear power industry, metallurgy industry, shipbuilding industry, airspace and aviation industry, transportation industry and important machinery manufacturing industry of the nation.

CNC floor type milling and boring machining center, series TH69, are not only provided with all the functions of the new floor type 5 axis milling machine, series TK69, but also with automatic tool changing function, and the magazine capacity can be customized upon customer's request.

Floor type 5 axis milling machine Other products in the same series:

TH6913B Series CNC Floor Type Milling And Boring Machining Center,

TH6916B Series CNC Floor Type Milling And Boring Machining Center,

TH6916 Series CNC Floor Type Milling And Boring Machining Center,

TH6920 Series CNC Floor Type Milling And Boring Machining Center,

TH6920A Series CNC Floor Type Milling And Boring Machining Center,

TH6926B Series CNC Floor Type Milling And Boring Machining Center,

TH6932 Series CNC Floor Type Milling And Boring Machining Center.

Advantages of floor type 5 axis milling machine:

1. Main transmission system of the machine is provided with multi-shift mechanical transmission and electric infinitely variable transmission, which provides a wide range of infinitely variable transmission for the main spindle. Main transmission motor is from qualified and professional manufacturers both in China and abroad.

2. The control system and the servo motor of the machine is from quali fied and professional manufacturers both in China and aboard. The CNC system is capable of seven axes control and simultaneous control on any four of them.

3. There is the spindle orientation provided for the machine.

4. New floor type 5 axis milling machine decelerates and stops quickly.

5. There are various compensation functions applied on the machine, and the application of the digital electro hydraulic proportional valves ensures the satisfaction of the requirements for spindle precision.

6. The spindle system is provided with independent cooling function, which can control the spindle temperature and ensure the spindle precision at high speed.

About packaging:

We choose to ship by sea, and the packaging is firm to ensure that your goods arrive safely and quickly. The delivery time is generally about 1.5~6 months. Regarding the payment method, you need to pay 30% in advance, and 70% of the balance can be paid before delivery.

Our social responsibility:

We have always deeply integrated social responsibility into corporate development. We comply with global quality and safety standards. From R&D and design to production and delivery, we strictly follow international certification standards in every aspect. We want to create value for our customers with reliable quality. While pursuing technological innovation, we actively practice the concept of green manufacturing and reduce our impact on the environment by optimizing production processes and energy management. At the same time, we have been engaged in industry talent training and community public welfare undertakings, using professional technology to give back to the society and help the sustainable development of the industry. This commitment to quality, environmental protection and social responsibility not only reflects our corporate responsibility, but also allows us to win the deep trust of our global partners. If you want to know more about us and our products, you are welcome to establish contact with us at any time!